Control Technology and Process Visualization

Our standard makes maximum process reliability possible.

Control, regulate, monitor, collect data, communicate and diagnose.

At ESA, automation (PLC programming) is based on a high-quality standard that has been tested extensively. The advantages for you lie in efficient program creation and a high level of consistent functionality at low cost.

Our library of modules for programming the control system is constantly being expanded based on real customer requirements. Every customer benefits from these enhancements.

We are always at the cutting edge of technology.

It's your choice.

The examples provided are just a small selection of possible options. We will be happy to present you with the optimum solution for you!

- Siemens CPUs

- Profinet/Profibus

- Remote I/Os

- Failsafe CPUs

- Redundant systems

We program new systems in the TIA Portal and expand existing Simatic S7 systems. Optionally, we offer control systems with Allen Bradley Control Logix.

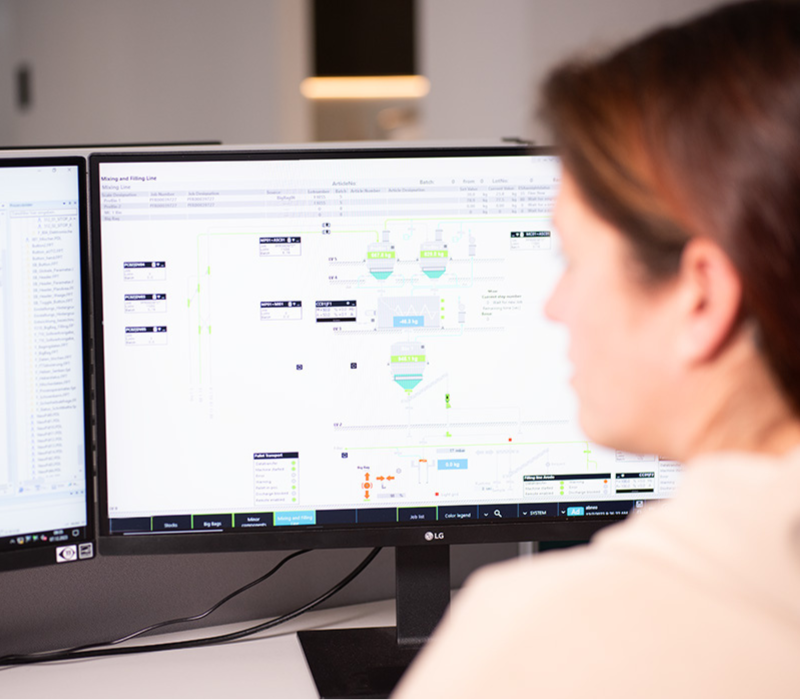

Complex process sequences presented simply and clearly.

Clearly arranged and displayed as well as visually consistent: the visualization provides a user-friendly insight into the control system and allows our clients to quickly intervene in all production processes. You are guided through formulas, can set activities and check system statuses.

Our visualization modules with standardized functions.

Sophisticated and tried and tested.

- attractive and clear design

- standardized connection windows per unit

- status information and trend displays

- access to stored documents for the respective unit

- user management linked to the process control system

- chronological event list

- Alarm and information overview including notification options via e-mail or SMS.

Depending on requirements or regulations, we use common visualization systems such as Siemens WinCC (TIA Portal), Win CC V7.x and Zenon.

We are full-service provider in the field of process automation.

With ESA, you have a reliable partner at your side. We support you from the comprehensive assessment of your requirements through to commissioning and ongoing support and optimization of your production system.

Consulting, Concept and Planning

Detailed needs assessment, a well-thought-out concept, and meticulous planning as a solid foundation.

Control technology and process visualization

High-quality standards enable a wide range of functions at low costs.

Electrical installations in process automation

Precisely planned and efficiently implemented - for a smooth commissioning.

Process optimization

Optimization of production facilities to maintain competitiveness, increase yield and quality.

Retrofit

Modernization of production facilities - increase efficiency, extend lifespan, and implement new functions.

Photovoltaics for businesses

Improve overall economic efficiency with tailor-made solar systems and storage solutions.