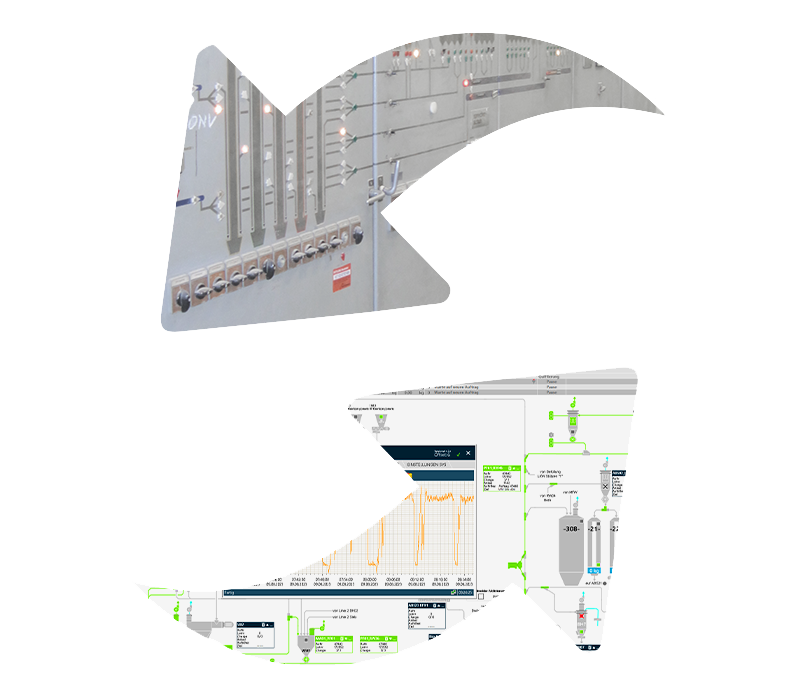

Retrofit: Modernization of production facilities

Increase efficiency, extend service life and implement new functions

The production system has become outdated. The risk of production losses due to plant downtime is increasing and performance and quality no longer meet the desired standard. At this point the facility operator must ask themselves the question: New plant or modernization?

There are many reasons for retrofitting. It is clear that, in the best-case scenario, modernization doesn't only save costs.

Extending the service life of the system, reducing production costs and increasing productivity and quality go hand in hand with a skilfully implemented modernization.

Cost savings

The ranking of reasons for retrofitting usually leads with the prospect of cost savings compared to a complete new purchase. A precise analysis of the local conditions and a resulting weighing out of costs and benefits is essential before the start of the project.

ESA leaves nothing to chance. We look at every little detail in advance so that we can give you a precise quote and an exact plan of the modernization process.

Minimal interruption to production

Modernization in the form of a retrofit or conversion of your system can usually be carried out with little or no interruption to production. Here too, it is important to take a close look at the general conditions in production in advance. If possible, a plant shutdown would be scheduled during non-production times (e.g. at night or at the weekend).

At ESA, we do everything in our ability in order to ensure that your production system is back in operation at the agreed upon time. Experienced technicians are also on call to intervene quickly in an emergency.

Everything is business as usual

If you have previously worked with the ESA system, your employees do not require extensive training or further training to be able to operate the system.

If you switch to the ESA system in the course of modernization, your employees will be familiarized with the new conditions during the production changeover and production support.

The retrofitting process

Planning is everything

We at ESA are experienced in the modernization of production facilities and know what we need to pay attention to in order to ensure a smooth transition. Close cooperation and feedback from our customers is very important to us.

We make an initial inspection of the conditions on site to get an overview.

When would a standstill be possible? How can this be bridged (e.g. by pre-production)? When must the facility go back into operation? etc.

What is the process like currently and what should it be like in the future? What adjustments are necessary and within the realms of possibility? etc.

In the case of major modernizations, a factory acceptance test is carried out before the production changeover: The client is able to experience the software under real conditions and, if necessary, make changes.

We provide our clients with intensive support during this phase. Employees are also trained in the new system during this period. Depending on the size of the project, this support lasts from one to several days.

"We support you in creating the ideal solution for you. We examine your production facility from all angles and consider a wide range of aspects: What is the general condition of your facility? Can the desired product capacity and quality be achieved through modernization? Will retrofitting enable you to meet legal requirements and safety regulations? The answers to these and other detailed questions form the basis for deciding how to proceed."

Christian Bergmayr | ESA expert for the modernization of production plants

We provide comprehensive advice on the options for modernizing your production system.

We are professionals in the modernization of production facilities.

Decades of experience and a large number of successfully completed retrofittings make us the ideal partner for your investment in the future. Regardless whether you are currently working with the ESA system or want to change over. We know our way around!