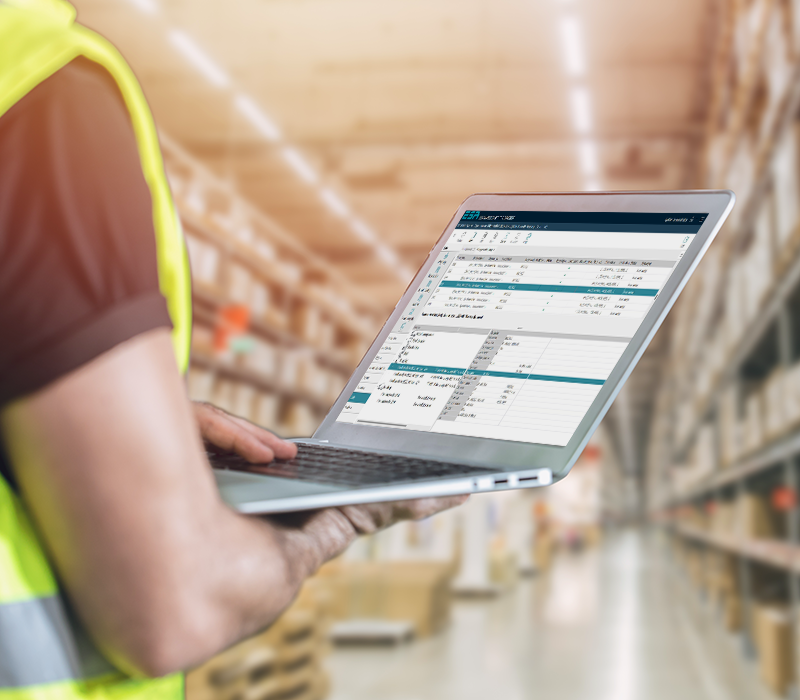

All data at a glance.

At all times. At every system point.

Compliance with hygiene and safety standards is a basic prerequisite for the production of high-quality food products.

ESA provides the right tools for maximum and effective control and monitoring of all production processes. Our process control system makes it easy to plan the exact order sequences with the lowest possible number of cleaning cycles and in compliance with high hygiene and safety standards.

Production gaps are made visible, which optimize production performance.

Our data visualization module illustrates all production processes at each individual system point, at any given time. This makes it easy to determine where, how much and how often production has taken place. Gaps in production planning can easily be identified and closed.

We are the specialists when it comes to weighing, mixing, and dosing raw materials.

Our sophisticated automation concepts, in combination with our state-of-the-art and highly customizable process control system, guarantee consistent high quality for your products, even with complex requirements and large production quantities.

We guarantee 100% traceability and transparency in every single step of your production.

Simple searching and quick retrieval is supported by various search criteria and a clear user interface.

Highlights from our process control system for the food industry

We support all process steps in the food industry, from the receipt of raw materials to the delivery of your finished goods, as well as in connection with all logistical processes.

At ESA, you receive your customizable process control system, including raw material warehouse management, in a solid overall package.

24/7 Automation Hotline. We won't leave you on your own.

Even after your production system has been commissioned, we are always at your side. In the event of problems in the production process or technical questions, you can contact your personal support 24/7. They are familiar with the special conditions of your system and can also provide you with optimum support via remote maintenance.

The smooth operation of your production system is of the utmost importance to us. Thus, we attach great importance to excellent availability, fast response times and a perfectly coordinated and well-trained hotline team. Our support team is based at ESA company headquarters in Upper Austria and consists of specialists with expertise in all aspects of automation.

Your contact person for the food industry:

Stefan Matschiner

Phone +43 676 88 75 15 83

Email s.matschiner@esa.at

We have long-standing and successful partnerships with our customers.

As part of our success stories, we present a small selection of projects from the food industry that we have planned, implemented and supported to date.

We are proud of our customers

We supply high-end automation solutions for your production facility.

ESA focuses on individuality and flexibility in all areas: Consulting, planning and project management, control technology and visualization, a sophisticated process control system, electrical installations and switch board construction as well as full-service support that leaves nothing to be desired.