Process control system ESAweight

Optimized for production facilities in the bulk material industry.

Modular construction. Individually adaptable.

ESAweight offers everything you need to control your system.

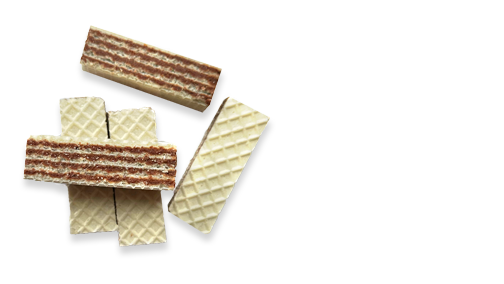

Our modular process control system has been developed for the specific requirements of production plants where bulk materials, viscous and liquid substances are processed.

ESAweight is configured for the processes of your production and your complete flow of goods and can be modularly expanded and individually adapted to your requirements at any time.

In addition, a variety of elements of a classic Manufacturing Execution System (MES) are covered, such as production management or the comprehensive collection of operational data.

Since the introduction of the process control system ESAweight, our team in Wolfern has been continuously working on the improvement and expansion to provide our customers with new key features.

Regular updates ensure that all our customers are constantly up to date with the latest technology and benefit from the extensions of other projects.

A simply ingenious solution with ESAweight.

Our process control system impresses with a comprehensive base and sophisticated additional modules. Individual requirements can be flexibly covered at any time.

ESAweight Manager

The solid foundation.

ESAweight Manager is the core of our process control system.

Based on the respective customer requirements, we have continuously developed and improved the ESAweight Manager over the years. Today, with its wide range of basic functions, it ensures central and user-friendly management of your production plant. In the ESAweight Manager, all plant-specific areas, such as lines, stations, scales, warehouses, etc., can be freely configured.

ESAweight Module

The modules that are perfectly suited to you will be utilized, depending on your process requirements. This makes your entire production process from raw material acceptance to delivery of your finished goods comfortable, consistent, and traceable. All modules can be flexibly integrated into your system at any time.

100% Flexibility and Individuality in all areas.

Every production plant is individual. The modules listed here represent a small selection of the most integrated ones and can be supplemented by a variety of industry-specific production modules.

If an area cannot be covered with one of our numerous, practice-tested standard modules, we have the know-how and flexibility to implement and integrate 100% of your set requirements into the system, whether a specific area or complete customization.

Our standardized interfaces ensure compatibility with all common warehouse management and driverless transport systems.

ERP systems

Import and export of master data as well as order data and any other information

Warehouse management systems

Automatic request of your production components triggered by minimum stock levels and order-related replenishments

Driverless transport systems

Transmission of transport orders for timely collection of raw materials in the production process, through intelligent route optimization of containers

ESA Support

We won't leave you to do it alone!

With ESA, you have a strong and reliable partner by your side. From the initial idea and planning through to the professional commissioning of your production system, production support as well as the training of your employees.

During operation, our experienced in-house support team is available to you 24/7 and can provide you with optimum support via remote maintenance.

We are your partner for the automation of production plants in the bulk material industry!

30 years of industry know-how and more than 200 successfully completed projects

Our experienced industry contacts are happy to introduce our company, our services, and our process control system to you.

We are proud of our customers

Our high-end solutions for automation of your production plant

From consultation and conception to optimizations and savings in existing production plants

Consultation, Concept and PlanningControl technology and process visualizationElectrical installations in process automationProcess optimizationsRetrofit: Modernization of production plantsPhotovoltaics for companies