Base Module ESAweight Manager is the solid and comprehensive foundation of our process control system.

Tried and tested in practice for over 30 years and continuously developed, the ESAweight Manager now offers a wide range of basic functions for the central management of all requirements in your production process. The free configuration of all system-specific processes ensures a high degree of customizability.

ESAweight covers 100% of the traceability required by EU Regulation 178/2002 - and even more:

- Complete and clear traceability from the delivery of the raw materials to the delivery of the finished product

- Batch Traceability

- Evaluation of all product flow data throughout the entire automation process

- Search and retrieval: various search criteria can be defined by batch code as well as by supplier, customer, lot, etc.

- Resetting of sampling

- Convenient tree views with a direct link to the process log

The ESAweight Manager allows you to configure your system based on your physical conditions. Lines, stations, scales, warehouses/silos etc. are created and production processes are mapped.

From master data such as raw materials and packaging to production and mixing recipes, data can be easily managed with or without interfaces.

By assigning individual user rights, ESAweight enables you to precisely define workstations and only assign relevant functions to the respective production steps.

Plan your process steps from goods received through production to delivery of your ready-to-sell products.

Control and manage your inventory. The ESAweight Manager is able to display loading aids such as pallets, bins or containers as well as packaging such as cartons, sacks or Big Bags in materials management in batches. Functions such as stock (per) offer you the opportunity to view your inventory live or retrospectively.

Evaluations and declarations can be created and customized using the integrated report editor including client management.

- Evaluations of production processes (from acceptance to delivery)

- Plant processes and trend evaluations

The ESAweight Manager (and all additional modules) is available in many languages and is constantly being expanded. The language selection is installation-independent and can be changed at any time as required.

The ESAweight Manager is based on specific practical requirements and is continuously being developed further.

The pool of extensive functions for production, merchandise management, logistics, maintenance and management enables transparent and optimum ease of use.

Interested in more?

Our process control system and the associated data sheets are very comprehensive. We would be happy to make a preselection for you and send you details!

Please fill out the form below to receive the desired datasheets.

Based on MS SQL database and MS Windows, the data in the ESAweight Manager is managed centrally.

All production data is reported back directly from the individual stations to the ESAweight database and can be retrieved and processed accordingly. The report editor integrated in the Database, including client management, creates individually customizable evaluations and declarations.

ESAweight Module

Depending on your process requirements, the modules best suited to your needs are utilized. This makes your entire production process, from the receipt of raw materials to the delivery of your finished goods, convenient, consistent and traceable. All modules can be flexibly integrated into your system at any time.

Traceability

The traceability included in the base (in accordance with EU/VO 178/2002) guarantees 100% transparency in every single step of your production.

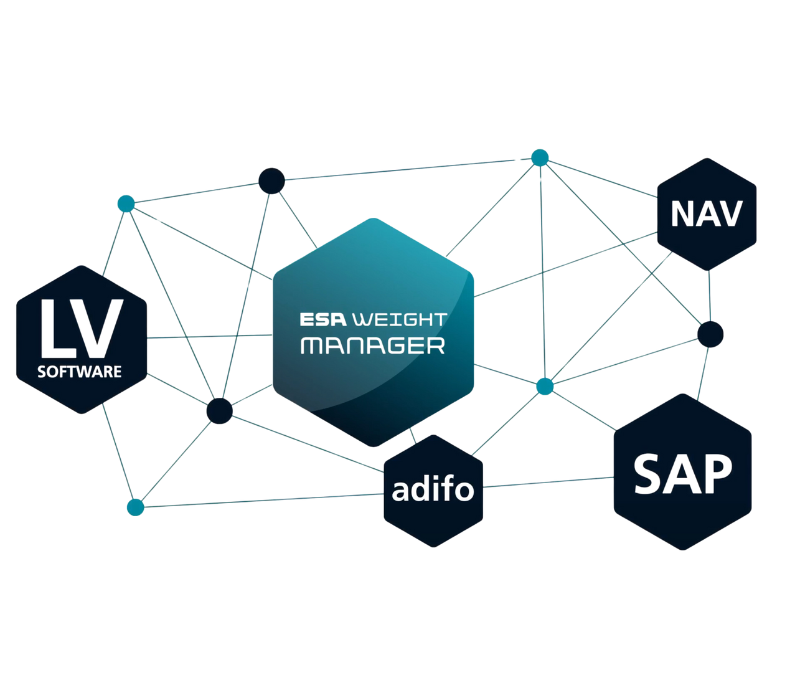

Exchange of Data

Your third-party systems are connected to ESA's process control system to ensure smooth communication. All common warehouse management and driverless transport systems can be integrated via standardized and customized interfaces.

ESA Support

We won't leave you to do it alone!

With ESA, you have a strong and reliable partner by your side. From the initial idea and planning through to the professional commissioning of your production system, production support as well as the training of your employees.

During operation, our experienced in-house support team is available to you 24/7 and can provide you with optimum support via remote maintenance.

We have long-standing and successful partnerships with our customers.

As part of our success stories, we present a small selection of projects that we have planned, implemented and supported to date.

Complex processes?

We love challenges!

Our standard modules are able to cover a wide range of requirements. We flexibly expand and adapt processes in order to meet the indivudual needs of our clients.

We work closely with you to develop the optimum solution for your production system.