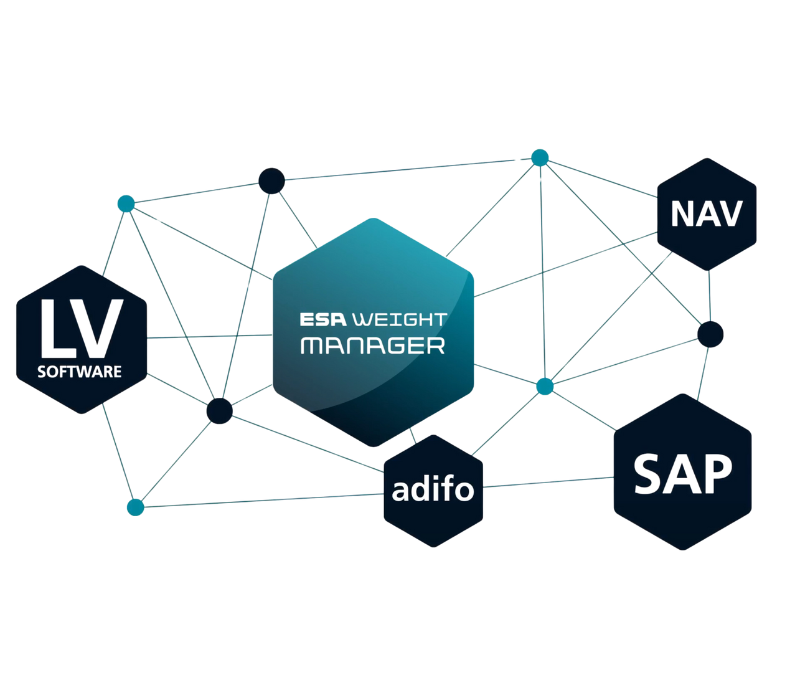

100% communication between systems

Data exchange

With our standardized software solution, we can connect your ERP system to ESA's process control system, integrate it into your system landscape and thus ensure smooth communication between the systems. This significantly reduces sources of error and the effort involved in multiple data entry and master data management. Examples of connected ERP systems:

Our interfaces: Standardized, yet individual. The groundwork of our software solution is standardized and can easily be individually adapted to your requirements as well as the requirements of your ERP system. We would be happy to work with you to define these specifications for our interface.

Our interfaces ensure compatibility with all common warehouse management and driverless transport systems.

LVS System AKL

LHM storage / LHM retrieval for weighing / LHM conversion to order container / LHM order container retrieval / LHM retrieval for quality inspection / LHM retrieval for inventory sampling

LVS System Full Pallet

Raw material request Daily silo filling / Raw material request Whole container input / Stock receipts BigBags from filling

AGV (APM) - Automated guided vehicle systems

Transmission of transport orders / feedback / status of transport orders and container number / live data

Completeness and plausibility of the data. The leading system is determined in the respective data area. When the data is imported, it is checked for completeness and plausibility. This means you can be sure that you are always working with the correct data and recipes (also from optimization programs such as Bestmix or Hybrimin).

Interested in more?

Our process control system and the associated data sheets are very extensive. We would be happy to make a preselection for you and send you details!

Please fill out the form below to receive the desired data sheets.

Our other modules are flexible, customizable, and can be expanded as needed.

ESA Support

We won't leave you to do it alone!

With ESA you have a strong and reliable partner by your side. From the initial idea and planning through to the professional commissioning of your production system, production support as well as the training of your employees.

During operation, our experienced in-house support team is available to you 24/7 and can provide you with optimum support via remote maintenance.

We have long-standing and successful partnerships with our customers.

As part of our success stories, we present a small selection of projects from various sectors that we have planned, implemented and supported to date.

Complex processes?

We love challenges!

Our standard modules are able to cover a wide range of requirements. We flexibly expand and adapt processes in order to meet the indivudual needs of our clients.

We work closely with you to develop the optimum solution for your production system.