The Exact Measurement with Certainty

Manual Dosing

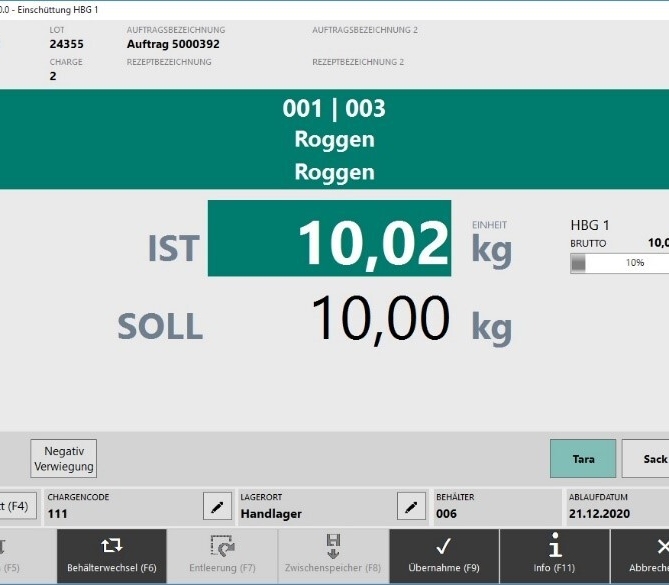

In manual dosing,the required components are weighed manually from various containers or automatically conveyed boxes. The operator is guided step by step through the recipe on the touch monitor. Barcode-supported product identification ensures traceable safety at all times. Examples of the tasks covered in the area of manual dosing:

Each dosing station only receives the data relevant to this production point. Depending on your production structure, both a currently required order can be dispensed and any random pre-production can take place. An unlimited number of dispensing stations can be involved.

Tobias Steinmayr | Software Development

The component sequence is possible both in batch order - as an automatic component sequence -or in any order by managing the labeled containers.

Container labels are created automatically by the system as required. This makes it possible to clearly assign each container to a production lot or batch. Any container change can also be carried out during dosing by scanning the labels.

Tolerance ranges can be defined individually. If a quantity dosed is within the tolerance range, the switch to the next component is activated. Desired tolerance overruns can only be confirmed by operators with sufficient authorization and can be viewed in the dosing log.

Interested in more?

Our process control system and the associated data sheets are very extensive.

We would be happy to make a preselection for you and send you details!

Please fill out the form below to receive the desired data sheets.

Mobile Dosing Station ESAmobile

Precise dosing wherever you need it.

The mobile dosing station enables efficient and precise manual dosing anywhere in your production. The station is equipped with an industrial PC and can be connected to the central system via WLAN.

Our other modules are flexible, customizable, and can be expanded as needed.

ESA Support

We won't leave you to do it alone!

With ESA you have a strong and reliable partner by your side. From the initial idea and planning through to the professional commissioning of your production system, production support as well as the training of your employees.

During operation, our experienced in-house support team is available to you 24/7 and can provide you with optimum support via remote maintenance.

We have long-standing and successful partnerships with our customers.

As part of our success stories, we present a small selection of projects from the food industry that we have planned, implemented and supported to date.

Complex processes?

We love challenges!

Our standard modules are able to cover a wide range of requirements. We flexibly expand and adapt processes in order to meet the indivudual needs of our clients.

We work closely with you to develop the optimum solution for your production system.